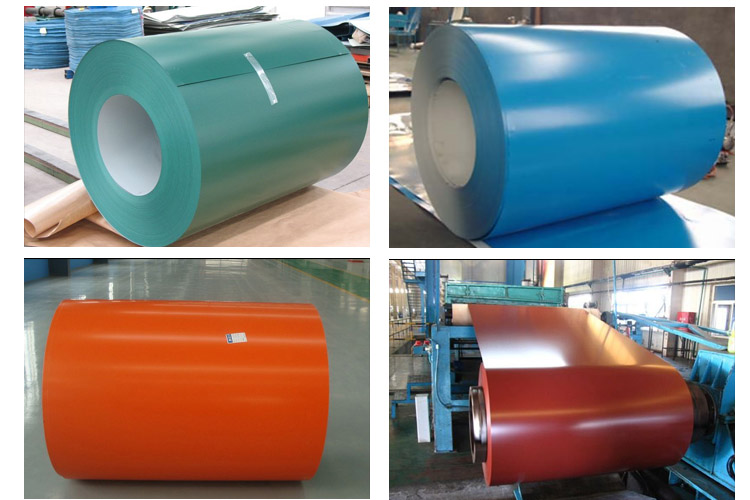

HaoMei---specializes in producing color coated aluminum coil for Exterior and Interior applications. Color coated aluminum coil is a salt with an excellent acid-resistant material. Coating to maintain a long light. It is an environmentally friendly, fire-resistant properties of the green and beautiful decorative.color coated aluminum coil are widely used in ACP,curtain panel,honey comb panel,shutter,roofing and most of the decoration areas. We have introduced in most advanced computerized metal processing equipment ,Pre-treatment by the German pharmaceutical Henkel and Kenema Mittel. PPG paint coatings using the United States, Sweden BECKER paint, the United States Lili valspar paint. PVDF, perfluorocarbons can be divided into surface coatings, self-cleaning nano-Kang Wu fluorocarbon coating, coated polyester, acrylic coating.With the superior quality and advanced management,our products had been export to Euro, Middle East, North America ,East Asia and many other areas and Countries.

With a large sales network, we have branches and offices in large cities. Adhering to the quality principle of "Quality Foremost, Customers Above All", we sincerely offer you perfect products and more comprehensive services.

HAOMEI color coated aluminum coils adopt the famous brandraw materials.It includes several classifications:

PE(polyester) Coating

PE(polyester) coating:high molecular polymer as monomer and addition of alkyd, is an UV-resistant coating. It can be classified matt and glossy according to coating gloss. The compact molecule structure, makes paint surface luster and smooth,which assure good printing on the panel surface. With an warranty of 8-10 years for weather resistance, it is specially applied for internal decoration and sign board.

PE Color Coated Aluminum Coil:

HAOMEI PE color coated aluminum coil with good PE Paints and high performance of aluminum coil is produced by advanced roller coating. All performance parameters are up to or much higher than related national standards.

The performance of PE color coated coil

| Item | Test Item | >Standard | National standard | Test Result |

| 1 | Color Difference | >ECCA T3 | ΔE≤2.0 | ΔE≤1.5 |

| 2 | Gloss Difference | >ECCA T2 | ≤10 | ≤5 |

| 3 | Coating Thickness | >ECCA T1 | Min 14µm | ≥16µm |

| 4 | Pencil Hardness | >ASTM D3363 | ≥HB | HB |

| 5 | T-bend | >ASTM D4145 | ≤3T | ≤2T |

| 6 | Adhesion | >ASTM D3359 | Grade 0 | Grade 0 |

| 7 | Impact | >ASTM D2794 | ≥20kg.cm | ≥20kg.cm |

| 8 | Boiling water Resistance | >GB/T17748 | 2h no change | 2h no change |

| 9 | Solvent Resistance | >ASTM D2248 | 200 times paint remaining | 200 times paint remaining |

| 10 | Salt Resistance | >ASTM B117 | 720 hrs≤grade 1 | 720hrs≤grade 1 |

| 11 | Dirt Resistance | >GB/T9780 | ≤5% | <5% |

| 12 | Color retaining | GB/T16259 | 600hrs △E≤2.0 | △E≤2.0 |

| 13 | Gloss weaken Level | 600hrs ≤ grade 2 | 600hrs ≤ grade 2 | |

| 14 | Chalking | 600hrs No Change | No Change |

PVDF(fluorine-carbon) Coating

PVDF(fluorine-carbon) coating :made of fluorine carbon resin, pigment, ester solvent, after high temperature roasting and baking, the paint is solidified to dry film with super weather resistance. PVDF coating also can be classified as traditional PVDF and nanometer PVDF coating.

A.Traditional PVDF Coating, with KYNAR500 PVDF, two or three times for coating and baking, has good properties of anti-acid, anti-alkali and is durable in atrocious weather and environment, keeping 15 years no unwonted fading. In view of these facts, we recommend this panel applied for external wall cladding.

B.Nanometer PVDF Coating, which different with traditional PVDF is the clear coating. It contains nanometer element, which can protect panel from pollution, Because nanometer has self-cleaning effect, It easy to get rid of dust and pollution by raining or water.

Parameters of PVDF Coating PVDF (KYNAR500 PVDF>70%)

Substrates: |

Aluminium (AA1100, 3003, 3004, 3105, 5006, 5052, 8011, etc), etc. |

Thickness: |

0.08-1.5mm |

Width: |

<1800mm |

Coils core diameter: |

150mm ,405mm, 505mm, 508mm, 510mm |

Coating thickness: |

PVDF >=25micron POLYESTER>=18micron |

Color standard: |

E < 2 or it is not obvious by eyeballing |

Pencil hardness: |

> 2HB |

Coating adhesive: |

not lower than first grade Impact: no any crack (50kg/cm, ASTMD-2794:1993) |

Bend stength: |

>100 times |

Boiling point: |

no any distortion and color change (in the 99 more or less 1 degree water, then cooling 2 hours) |

Corrosive: |

surface deep in the 5% muriatic acid and 5% NaCL, interior deepin the 2% muriatic acid and 2% NaCL, after 48 hours, no change |

For more color coated aluminum coil technical documents, Download free in PDF form !! (Haomei_color_coated _aluminum_coil.pdf)

zhengzhouhaomei Industrial Co., Ltd. in Xiangti Bay Hotel hosted the "2015 Annual Meeting of the New Year"Read more

hey are mainly visited our office and asked many questions about our Aluminium Cable Foil products on the scene. Read more

Tel: +86-371-65621391

Fax: +86-371-65621393

Mobile:+86-13938245529

Email:alu@haomeicn.com

Office Add: 1103, First Int., No.14 Waihuan Road, CBD, Zhengzhou, China

Zip code: 450000